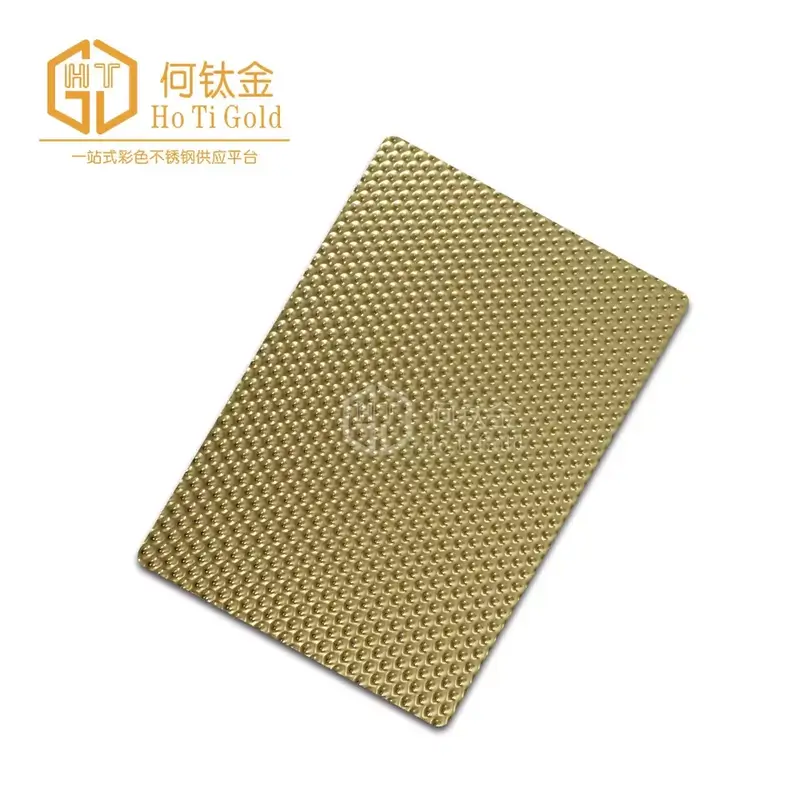

The stainless steel embossed sheet has an uneven pattern on the surface, which can play a non-slip effect to a certain extent. 304, 201 stainless steels are mainly used, and the concave and convex patterns on the surface are made by work rolls with patterns. There are many of these uneven patterns, such as small square patterns, twill patterns, wishful clouds and so on. These patterns have certain auspicious meanings in them, and also have practical functions.

Conventional stainless steel sheet sizes are as follows:

1000*2000mm, 1219*2438mm, 1219*3048mm; also can be cut to length, according to customer requirements, the whole roll can also be embossed. The thickness is 0.3-2mm. The general surface of the product also has a lot of patterns to choose from, so the most commonly used ones are the following: checkered pattern / diamond pattern / coarse hemp pattern / ice pattern / oval pattern / tile pattern / twill pattern / rice grain board / millet grain board / Beaded board/cube pattern/braided bamboo pattern/free pattern/die love flower/stone pattern. Stainless steel embossed sheets are not only suitable for decorating elevators, building decoration, metal curtains, and wall industries, but also widely used in innovative product design technology fields. Because the stainless steel checker sheet has fast and smooth conveying function, it is especially suitable for food machinery, pharmaceutical machinery, electronic weighing apparatus, freezer cold storage, building roofing, packaging and printing machinery, film printing, logistics equipment, transmission track/belt, urban rail transit vehicles And subway light rail vehicle automatic door and car body system. This stainless steel checker sheet is guaranteed not to stick to the conveyor belt or conveyed products.

Features of stainless steel embossed sheet:

1. Good-looking, durable, wear-resistant, visually beautiful, and of good quality.

2. Subsequent processing such as titanium plating and no fingerprints can be carried out.

3. There are more than 20 patterns, and the color can be selected at will.

4. The surface of the product is covered with PVC protective film, and the thickness is 3C/5C/7C/10C.

In many occasions, we can see their existence. When you go down the threshold of the stairs, you will choose to install this kind of stainless steel embossed sheet to prevent slipping, or some kitchen carts will choose to use stainless steel embossed sheet to increase friction. force to reduce slipping in the kitchen.

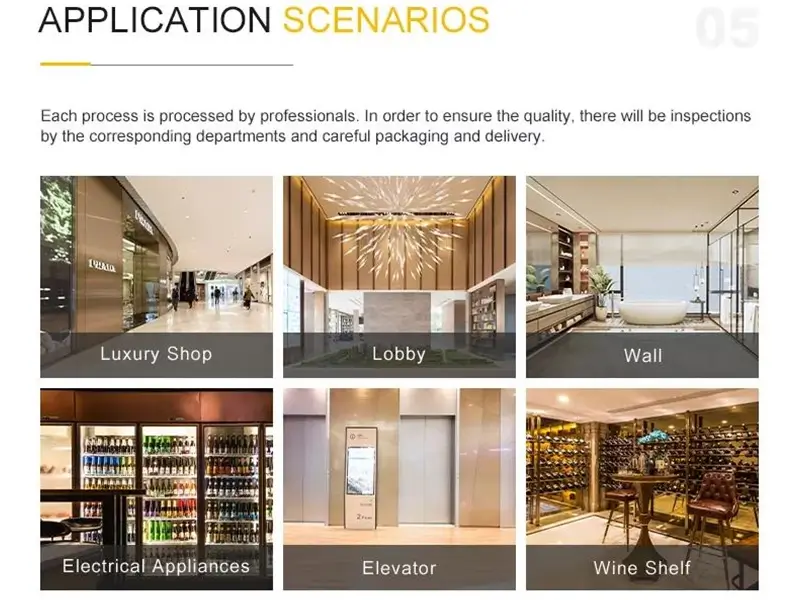

Application:

Stainless steel embossed sheet is suitable for decorating elevator cars, subway cars, various cabins, architectural decoration and metal curtain wall industries.

Why is stainless steel embossed sheet so popular?

1. Easy installation and short construction period. Because metal embossed boards have certain specifications and are more easy to install, metal embossed boards have better performance, so the installation will not be affected by climate or geographical location. This can effectively shorten the construction period, speed up the process of work, save the overall cost for the business, and ensure a high profit margin.

2. Excellent thermal insulation performance. We all know that energy saving and environmental protection are advocated now, so how can we achieve energy saving and environmental protection in the process of decoration? The metal embossed board can effectively ensure the effect of heat preservation and heat insulation, which can ensure that the indoor temperature is constant, and also reduce the heat loss, which naturally helps us save more energy. Compared with the traditional external wall insulation board, the metal embossed board has very good cold resistance and thermal insulation performance, and the cost is also lower.

3. Anti-shock and anti-crack, longer service life. The metal embossed board has strong shock and crack resistance, and has very good impact resistance, and when used outside the building, it can greatly reduce its impact on the building. Especially on some light steel structure buildings, it is especially suitable to use such embossed boards, which have stronger seismic performance and higher practicability.

Foshan Hotigold Stainless Steel Co., Ltd. is committed to the development and research of the surface of high-grade stainless steel sheets, and has the most advanced complete set of production equipment, production experience and technology of surface treatment of stainless steel decorative sheets. Adopt strict quality management system and product testing! It has gradually become the most dynamic and creative high-end stainless steel decorative sheet manufacturer in the market. Our products are widely used in: star-rated hotels, high-end clubs, high-end villas, elevator decoration, luxury doors, hotel lobbies, outdoor projects, curtain walls, kitchen utensils, walkway boards, facades, etc., as well as various stainless steel products, we can customize all the stainless steel products according to customers different needs, so we can make the most suitable products for customers, and meet the needs of customers with sufficient supply, preferential prices and high efficiency.