An the stainless steel industry, the 8K mirror stainless steel sheet is also known as: mirror sheet, mirror light sheet, mirror stainless steel sheet. Its varieties are divided into single-sided and double-sided.

Mirror stainless steel sheet finish grade

Then, the luminosity of the surface of the mirror sheet is divided into four mirror levels: 6K, 8K, 10K and 12K. The manufacturing materials of the mirror sheet: 2B and Ba sheet made of 201/304/316/430 and other materials are mostly selected as the base sheet.

Mirror stainless steel sheet production equipment

After rough grinding, medium grinding and fine grinding on the surface of stainless steel plate with grinding fluid through polishing equipment, a bright surface effect can be obtained, which can reflect people like a mirror, and is called the mirror. Of course, if necessary, people can also use its reflective surface to tidy up their appearance, haha. Then the mixing of grinding fluid is: water, nitric acid and iron red powder are mixed in a certain proportion. If the proportion is adjusted well, the higher the quality of the product will be, and the plate will certainly have more texture!

Mirror stainless steel sheet production process flow

Next, let’s introduce the polishing process:

1.Rough polishing: generally use grinding wheel: 80 # 120 # 240 # 320 # 400 # 600 # arranged in order from coarse to fine. Note (ps:80 # is the coarsest) this process is generally ground with clean water, and six groups of grinders are generally used, mainly to remove rough surface, burrs, sand holes, etc. of course, this process has a certain depth, about 0.11 ~ 0.22mm. The surface obtained is: fine sanding, which has a certain luminosity.

2.Fine polishing: as long as the machine-made wool felt is used, the higher the density, the better. In this process, water, nitric acid and iron oxide powder are used for grinding. Generally, ten groups of grinding machines are used without depth, mainly to remove the oxide layer, sand holes, rough grinding head flowers (also known as grinding head flowers and grinding head lines) on the surface of the plate, improve the brightness and highlight the details.

3.After finishing the above two polishing processes, we will move to the next process: washing and drying: this process is cleaned with clean water. The thinner the brush used, the better. The cleaner the water is, the cleaner the washed product will be. Then we will dry it with a baking lamp!

4.After the drying procedure, quality inspection is essential: check the brightness, the number of trachoma, whether there is peeling line, dark bone, scratch, whether the product is deformed, and whether the grinding flower is within the control range. Otherwise, the product quality is not up to standard.

5.Finally, paste protective film for packing: this process is mainly aimed at the finished products that meet the standards. Requirements: the protective film should be pasted smoothly, there should be no edge leakage, and the cutting must be neat. Then it can be packed and shipped.

In conclusion

Double sided 8K mirror sheet: the process is roughly the same, the difference is that when grinding the first front, first use a plate of the same size to pad the bottom to prevent the reverse side from being scratched, grind the front side and paste the protective film, and then use the pad to grind the reverse side. The process is the same as above. Finally, grind and paste the protective film, and then replace the dirty protective film on the front side, that is, the finished product.

Because double-sided 8K board is more time-consuming and higher wood forming than single-sided panel, the processing cost of double-sided 8K board in the market is about three times that of single-sided 8K board.

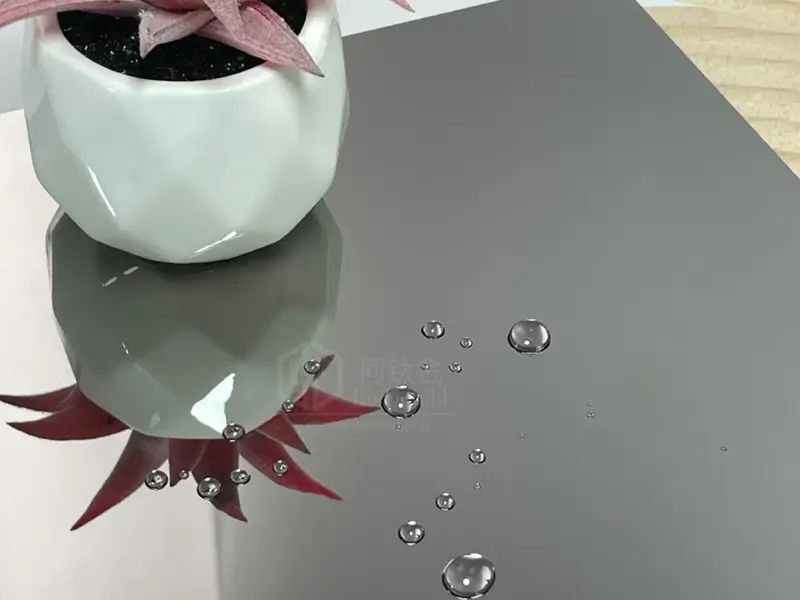

The most common mirror stainless steel sheet in the market should be “8K” in the stainless steel industry. The purpose of 8K mirror sheet is: stainless steel 8K sheet series products are widely used in stainless steel decoration projects such as architectural decoration, stainless steel shower room, kitchen and bathroom, elevator decoration, industrial decoration, facility decoration, etc. Using it to decorate the space can not only show the shiny and beautiful quality of stainless steel, but also make the sense of space larger.

At the same time, it also has strong corrosion resistance, high temperature resistance, wear resistance and scratch resistance. It has good processing performance. It is a very excellent metal decorative material!