Stainless steel etched sheets can make all-encompassing patterns, patterns can also be customized, and even unique styles and patterns can be customized. How did the seemingly magical craftsmanship come out?

The Processflow:

Stainless steel sheet-degreasing-washing-drying-screen printing-drying-water immersion-etched pattern leaf (sheet) washing-inkremoval-washing-polishing-washing-coloring-washing leaf (sheet) hardening treatment-sealing treatment-Clean the leaves (sheets) and dry-test-product.

General Material:

Stainless steel 8K mirror sheet, stainless steel wire drawing sheet(models: 80, 120, 180, 240, 320, 400, 600), stainless steel snow sand, ordinary sand, sandblasting, etching on various colored stainless steel sheets.

Stainless Steel Sheet Specification:

1000mm*2000mm

1219mm*2438mm

1219mm*3000mm

1219mm*3048mm

1219mm*4000mm

Standard is 1219mm*2438mm

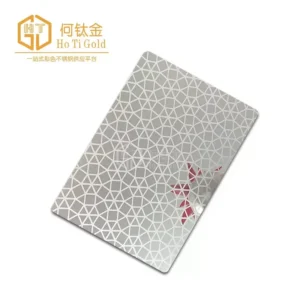

Etched Sheet Introduction:

In fact, stainless steel etching sheet is a new corrosion sheet formed by mirroring, wire drawing, etching and other processes on the surface with 201/304/316 stainless steel, copper, iron and aluminum as the base material. Stainless steel etched sheets can be made of two kinds of vacuum plating and water plating, which can force the product to have pure color, high corrosion resistance and high friction resistance. Through two corrosion processing methods of silk screen process or photosensitive process, the color stainless steel etched sheet and the color of colored stainless steel can be obtained. Different, such as titanium black, sky blue, titanium gold, brown, purple, bronze, green, etc. The stainless steel etching sheet realizes the effect of bright and dark patterns and brilliant colors. The stainless steel sheet processed by stainless steel etching is more resistant to corrosion and wear, and is not easy to rust. The etching process is generally divided into shallow etching and deep etching. As the name implies, it is the depth of etching. If the etching depth is lower than 5C, it is shallow etching. The deep etching pattern has obvious unevenness and strong hand feeling, and photosensitive etching is basically used.

The color stainless steel etched sheet has higher wear resistance and scratch resistance than ordinary stainless steel. It will not rust or fade in the atmosphere, rain, and humidity, making it an ideal decorative material. Commonly used in hotels, guesthouses, entertainment venues, high-end leather brand stores, carriage panels, hall wall panels, ceilings, signboards, door and window decorations, etc. Therefore, stainless steel etched sheet is an artistic embodiment of adoption in the process of modern art decoration.

In modern technology, stainless steel etched sheets cannot be used for high-precision and refined products. Its etching process is very suitable for precision products, such as automotive mechanical parts, gaskets and spacers, high-performance sealing gaskets, various filters The mesh, electric vehicle battery, and car horn mesh all use the etching process.

Stainless steel etched sheet has strong corrosion resistance (especially color etched stainless steel after color plating), can resist more than 10 years of salt spray corrosion and more than 30 years of ultraviolet light without discoloration, so in the long run, stainless steel etched sheet is very cost-effective, can help customers save a lot. It has strong processing performance and can meet various requirements of customers. Do decoration, show high-end. In the enjoyment of the beauty of the audience, and the price is affordable.

The Advantages of Stainless Steel Etched Sheet:

(1) Compared with embossing, the pattern is more irregular, and complete patterns such as landscape paintings can be processed.

(2) The decorative effect is good.

(3) Strong corrosion resistance.

(4) Its wear resistance, scratch resistance and scrub resistance are also very strong.

(5) Strong machinability. After the stainless steel is etched, the surface of the object can be further processed. The stainless steel etched sheet can be processed by various complex processes such as partial and patterning, wire drawing, gold inlay, partial titanium gold and so on.

Foshan Hotigold Stainless Steel Co.,Ltd has been committed to the research and development and production of high-end decorative stainless steel. It has the most advanced stainless steel surface treatment equipment, as well as the best production team and technicians. It is the most complete and technologically advanced production enterprise in the market. The products are favored by well-known designers and owners at home and abroad, and are widely used in the decoration of high-end real estate, hotels, business centers, elevators, villas and exhibition centers.